Hitachi excavator ZX670LC(4479885,9194674,HT975)front idler ass'y/welding and forging idler source factory-DPW parts

Hitachi excavator ZX670LC(4479885,9194674,HT975) front idler group/hitachi rollers factory

Forging Idlers (Forged Track Idlers) in Undercarriage Systems

Forged idlers (or forging idlers) are heavy-duty track rollers used in the undercarriage of crawler machinery like excavators, bulldozers, and track loaders. Unlike cast idlers, forged idlers are made through a forging process, which enhances their strength, durability, and resistance to impact and wear.

Key Features of Forged Idlers

✔ Superior Strength – Forging aligns the metal grain structure, making them tougher than cast idlers.

✔ Higher Load Capacity – Ideal for heavy-duty applications in mining, quarrying, and large excavators.

✔ Better Impact Resistance – Less prone to cracking under shock loads.

✔ Extended Service Life – More resistant to wear, reducing downtime and replacement costs.

Types of Forged Idlers

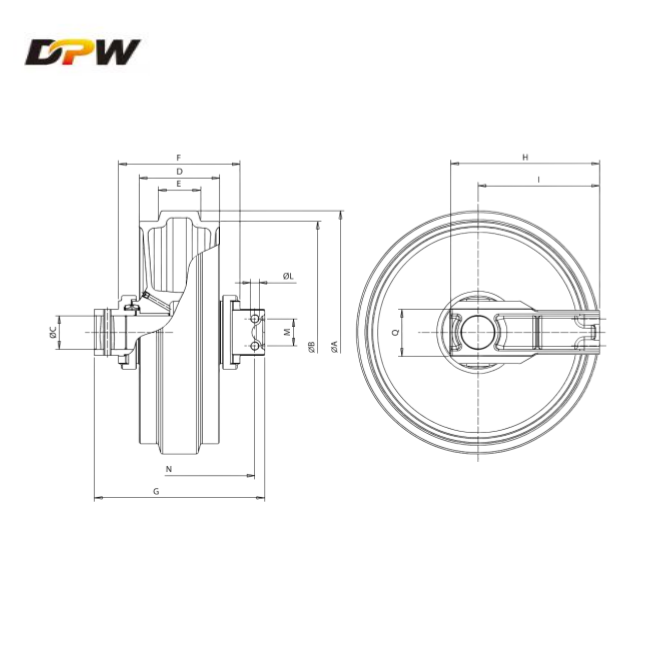

Front Idlers (Guide Idlers)

Positioned at the front of the undercarriage.

Help steer and maintain track tension.

Often have a smooth or grooved surface for track alignment.

Bottom Rollers (Lower Track Rollers)

Support the machine’s weight and roll along the track chain.

Typically have a double-flange design for better track guidance.

Carrier Rollers (Upper Rollers)

Support the upper part of the track chain to prevent sagging.

Advantages Over Cast Idlers

| Feature | Forged Idlers | Cast Idlers |

|---|---|---|

| Strength | Extremely high | Moderate |

| Durability | Longer lifespan | Shorter lifespan |

| Impact Resistance | Excellent | Prone to cracks |

| Cost | Higher initial cost | More affordable |

| Applications | Heavy mining, extreme conditions | General construction |

Signs of Worn or Damaged Forged Idlers

⚠ Abnormal track noise (grinding, squeaking)

⚠ Uneven track wear (misalignment)

⚠ Visible cracks or deformation

⚠ Seized or stiff rotation (bearing failure)

⚠ Grease leakage (seal damage)

Maintenance Tips for Forged Idlers

✔ Regular cleaning – Remove mud, rocks, and debris to prevent premature wear.

✔ Proper lubrication – Some idlers require periodic greasing (check OEM specs).

✔ Inspect for wear – Measure diameter and flange thickness against OEM tolerances.

✔ Replace in pairs – Ensures balanced track tension and alignment.